High Temperature Continuous Operation

History of High Temperature Continuous Operation

- High Temperature Continuous Operation was conducted in a parallel operation mode with Primary Pressurized Water Cooler (PPWC) and Helium/Helium Intermediate Heat Exchanger (IHX).

- The HTTR started-up on January 5th, 2010, and kept rated thermal power from January 22. After that, 50 days continuous operation was achieved on March 13, at 5:00 p.m. The reactor power decreased from March 14 and stopped on March 21. Total operation was 76 days. As a result, the Effective Full Power Day (EFPD) reaches about 370 (more than half of the 660 EFPD which is the limited number of operation day).

History of the reactor power of high temperature continuous operation mode

Results of High Temperature Continuous Operation

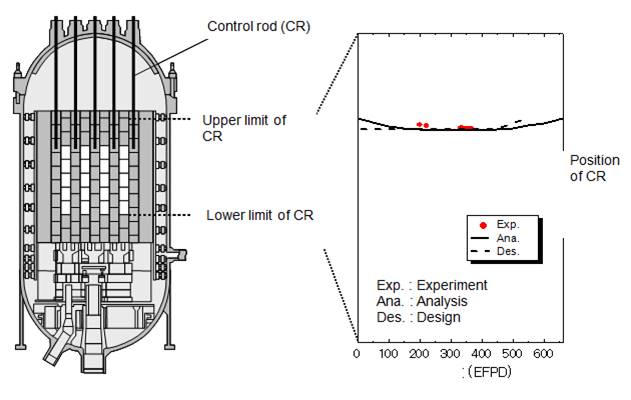

In the design of the HTTR, insertion depth of the Control Rods (CRs) into the core is limited less than 290mm to prevent unexpected power distribution. For this purpose, the power distribution of the HTTR was optimized by using several fuel enrichments and Burnable Poison (BP) concentrations. Through the operation, it was confirmed that the CRs insertion depth was less than 140mm. Also, we developed analytical method which can evaluate the CR position within 3% of error. By this method, it is estimated that the HTTR burnup can extend to 20%. This result enables to improve economy of commercial reactors.

Change in Control Rod Position

The design limit of Fission Products (FP) 88Kr release is 5 x 10-4. The fuel was fabricated by improvement of sphericity of coated fuel particles, prevention of collision damage in coating process, etc. In the operation, there was no coating failure by irradiation, and it showed very low FP release fraction comparing foreign experiences. It is confirmed that HTTR fuel has the highest quality in the world.

Change of 88Kr emission

Safety Demonstration Test

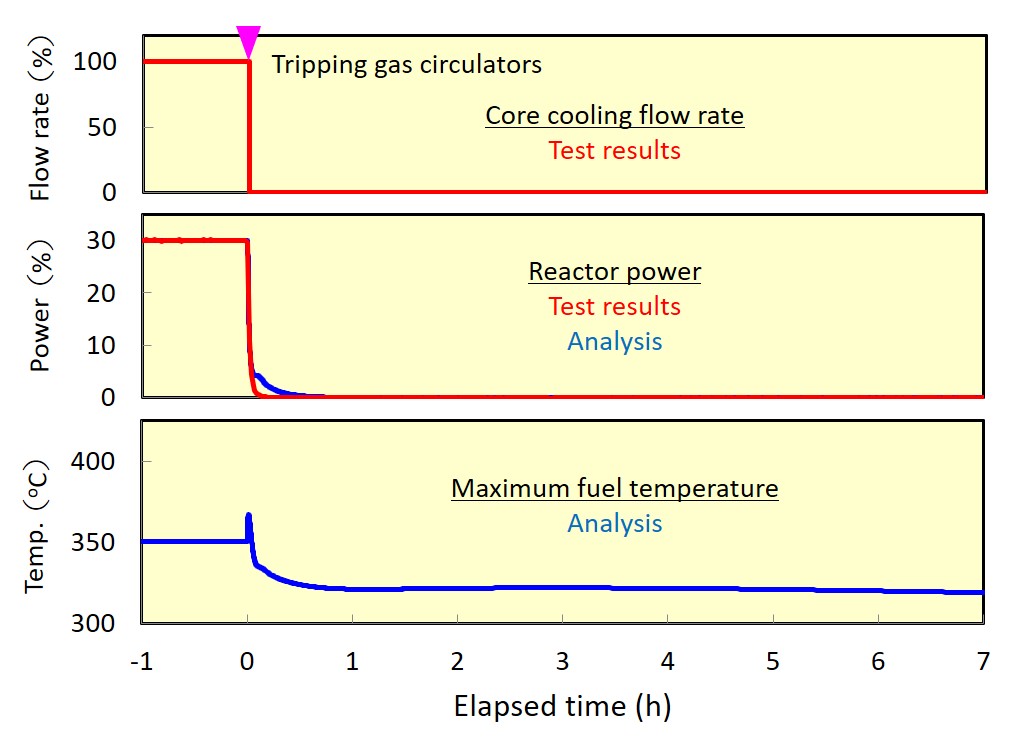

Loss of forced cooling test at 9MW (December 21th in 2010)

- The loss of forced cooling test (LOFC) in the HTTR was successfully completed under the condition of the reactor power of 9MW (30% of the rated power).

- To demonstrate the inherent safety features of HTGR in the case of LOFC, all of the primary helium gas circulators were stopped from the steady operation, although the reactor shutdown system is not operational. In the test, the reactor power decreased to about zero automatically and attained to stable state.

Loss of core flow test at 9MW (January 24th in 2011)

- The first loss-of-core cooling (LOCC) test using the HTTR was conducted. In the test, 1 of 2 residual heat removal systems of a vessel cooling system was stopped with stopping all primary helium gas circulators from the steady operation under the reactor power of 9MW (30% of the rated power of 30MW), although the reactor shutdown system is not operational. This is severer than the LOFC test performed on last December. The LOCC test is the first test in the world.

- Zero flow rate of the HTTR primary system was kept for 6 hours. The reactor power decreased rapidly down to about zero from just after the gas circulators' stoppage. And there was no unexpected phenomenon during the test.