Japan Atomic Energy Agency (JAEA) has been conducting a study on the hydrogen production process since 1980's.

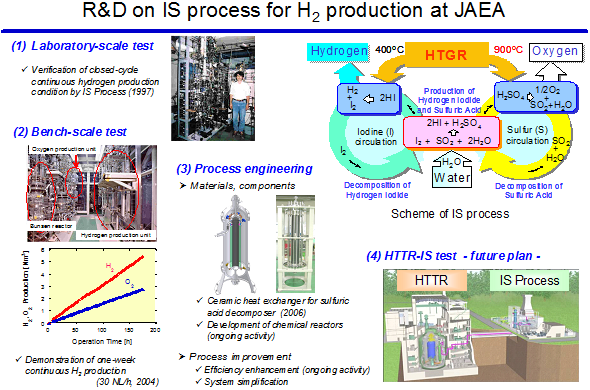

At first, JAEA performed a study on the chemical reactions and the product separations of IS process and found a suitable condition with which possible side-reactions could be suppressed and the closed-cycle operation could be realized. In 1997, the closed-cycle operation condition was verified with laboratory-scale hydrogen production experiments. In the next step, a methodology was developed to control the stable and continuous hydrogen production. Also, a composition measurement technique was developed which enabled the realization of the developed process control methodology. Owing to the achievements, a one-week continuous hydrogen production was completed in 2004 with the rate of 30 liter per hour using a glass-made bench-scale apparatus [1].

The third step is the process engineering. So far, work was carried out on the corrosion resistant components and innovative technologies for efficient hydrogen production, and on the technical database for the IS plant design. These efforts resulted in such fruits as the successful test-fabrication of a heat exchanger for sulfuric acid decomposer, which was made of silicon carbide that exhibited superior corrosion resistance in the concerned environments [2]. Based on the results, the present study focuses on the development of chemical reactors made of industrial materials and to verify their integrity in the high pressure and corrosive process environments. Another purpose of the study is to acquire process data for efficient hydrogen production with thermal efficiency of higher than 40%.

In the following step, it is planned to carry out the hydrogen production test coupled with the HTTR (HTTR-IS Test). The demonstration of nuclear hydrogen production will advance the development and deployment of commercial HTGR systems. 600MWth HTGR system designed for hydrogen production may supply hydrogen fuel to about 170,000 Fuel Cell Vehicles [3]. As such, the system has a high potential of contributing to the future hydrogen society that is expected to be realized in 2020's - 2030's.

- [1] Shinji Kubo, Hayato Nakajima et al., "A Bench Scale Hydrogen Production Test by the Thermochemical Water-splitting Iodine-Sulfur Process", GLOBAL 2005, Oct.9-13, 2005, Tsukuba, Japan, paper 474.

- [2] Press Release, July 4, 2006, "Development of Sulfuric Acid Decomposer featuring Ceramic Heat Exchanger for Iodine-Sulfur Hydrogen Production Process - Progress in R&D on Nuclear Production of Hydrogen -"

- [3] When calculating as hydrogen consumption 1000m3/y-car and hydrogen production rate 24000m3/h

The demonstration of one-week hydrogen production was performed in the Development of Nuclear Heat Utilization System in FY 2004 entrusted to JAEA by the Ministry of Education, Culture, Sports, Science and Technology of Japan (MEXT).

FAQ

- What is HTGR ?

- Structure of HTGRs

- Temperature Ranges Applicable to Various Industrial Fields

- Development Status of HTGRs in the World

- Outline of High Temperature Engineering Test Reactor

- Establishment of technical bases of high temperature gas-cooled reactor with the HTTR

- Various Hydrogen Production Methods

- R&D on Thermochemical IS Process

- Hydrogen Society in the Future