Laser beam has several features such as same wave-length, same-phase and beam traveling linearity. The beam, because of these reasons, is focused on a small area, and high-power density is easily obtained by optical devises. Non-contact, high-speed and precisely controlled laser irradiation are significant advantages as well, and therefore, laser technologies have been widely used in many industries.

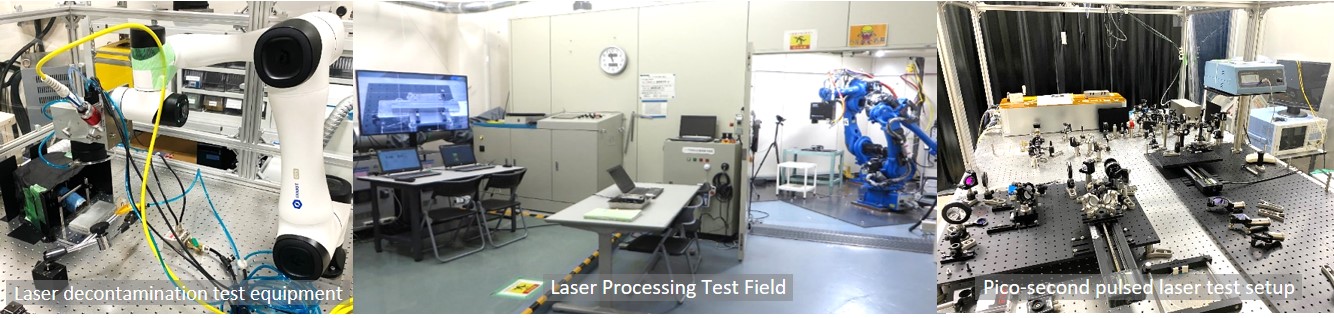

By taking account of these strengths, JAEA has developed laser cutting and laser decontamination technologies for nuclear power plants decommissioning. JAEA has also applied our laser technologies for industrial use, including laser quenching, laser rust-resistance and laser penetration plastic-resin joining.

These R&Ds activates are explained below, and a click of titles links to each content.

This website is updated with our R&Ds progress.

I. Applied Laser technologies for decommissioning

I-1 Laser cutting test equipment

I-3 Laser thermal processing analytical computer code

I-4 Laser decontamination using high-power density

I-5 Laser decontamination computer analysis (Metal surface de-lamination analysis)

II. Applied Laser technologies for industries and Laser science researches

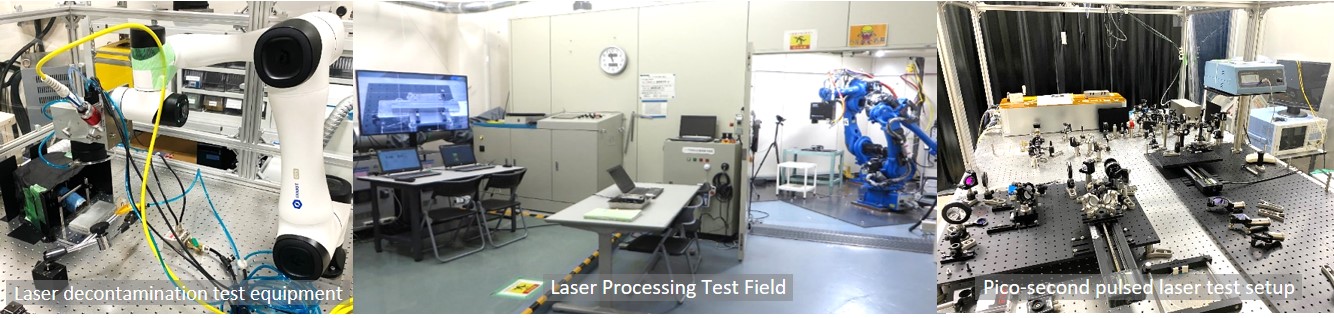

II-2 CFRTP (Carbon fiber reinforced thermo-plastic) cutting process using pico-second pulse laser

II-4 Computer analysis of laser penetration plastic-resin joining

II-5 Nonlinear QED plasma transport model in a high-intensity laser pulse