Characterization of fuel debris

Fuel debris is the solidified melt distributed among fuel assemblies, control rods, and some other reactor materials. The fuel debris is considered to be distributed not only within the reactor pressure vessels but also in the primary containment vessels. It is necessary to understand the characteristics of fuel debris for the efficient and appropriate operation of removal, storage, processing and disposal of the fuel debris.

Characterization, material properties, and chemical treatment

◎ Objective

The core melt mainly consists of fuels (UO2 and Zircaloy) and control rods (B4C and stainless steel), and it may even have reacted with the salt deposit from the injected seawater, pressure vessels (steel) and concrete at the bottom of the primary containment vessels. The constituents and characteristics of the solidified debris vary extensively depending on the conditions (temperature history, oxygen partial pressure) and the positions of solidification.

In order to determine the methods for removal, analyses, storage and disposal of fuel debris, it is essential to understand its chemical and physical characteristics such as compositions, phases, densities, microstructures, and mechanical and thermal properties.

◎ R&D activities

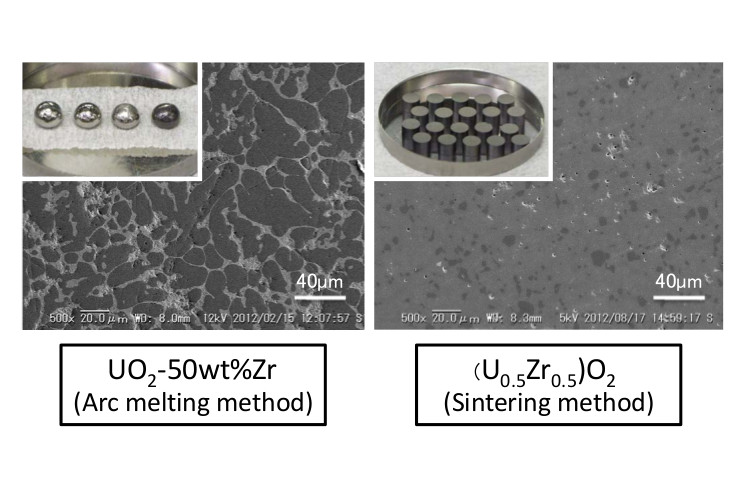

The actual fuel debris is planned to be sampled in the next few years. Until then, the characteristics studies are being performed using (U,Zr)O2 sim-debris. The various forms of high temperature reaction products among (U,Zr)O2, sea salt deposit, Zr, B4C, stainless steel and concrete are characterized by X-ray diffraction, microscopy and elemental analysis etc. Vickers hardness and thermal conductivity are measured to be included in the material property database. Additionally, the fuel debris sampled from the Three Mile Island accident will be used as reference material.

In parallel, the pretreatment techniques for dissolution, analyses and reduction or chlorination for reprocessing are also being studied.

◎ Related facilities

Various phases and microstructures resulting from different conditions of sim-debris formation

(U,Zr)O2 sim-debris heat-treated with an alkali for acid dissolution

This R&D contributes to part of the "Mid-and-Long-Term Roadmap towards the Decommissioning of TEPCO's Fukushima Daiichi Nuclear Power Station Units 1-4".

- (2-(3)-1) Study of Characteristics using Simulated Fuel Debris

- (2-(3)-3) Development of Technologies for Processing of Fuel Debris

Criticality control of fuel debris

◎ Objective

The control rods were degraded or displaced together with fuel assemblies when the core melted down, and their regular function to control the fission chain reaction was lost. This means that there is a possibility of re-criticality due to the condition change led by fragmentation in the coolant water during the fuel debris removal.

Criticality characteristics of the fuel debris that is a mixture of various materials must be investigated. Risk evaluation of re-criticality and development of countermeasures against the re-criticality event are also necessary for the safe handling of fuel debris.

◎ R&D activities

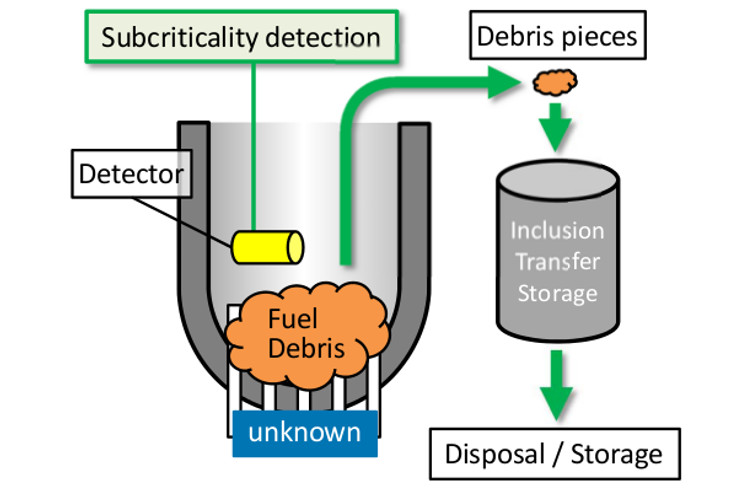

The critical masses for fuel debris with various compositions are being calculated to evaluate the re-criticality risk level of each operation such as fragmentation, removal and storage of fuel debris. For the operations with higher risk levels, the detection system of subcriticality is developed as the safety net of the re-criticality countermeasure.

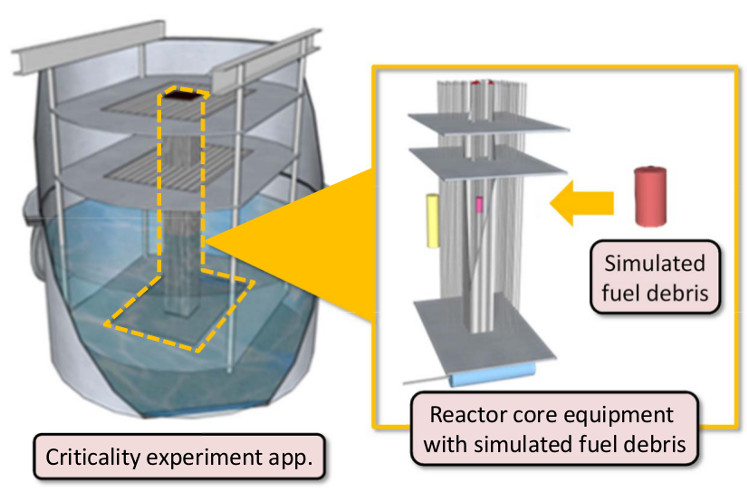

It is also important to validate R&D results before their application to the actual operations in Fukushima Daiichi NPP site. Therefore, a small reactor, so called "criticality assembly", is used to confirm the accuracy of critical mass calculations by measuring the critical mass of the simulated fuel debris, or to demonstrate countermeasure reliability by testing sensitivity of neutron detectors and effectiveness of neutron poison.

◎ Related facilities

Concept of criticality prevention

Criticality experimental apparatus to measure the critical amount of simulated fuel debris (concept)

This R&D contributes to part of the "Mid-and-Long-Term Roadmap towards the Decommissioning of TEPCO's Fukushima Daiichi Nuclear Power Station Units 1-4".

- (2-(1)-9) Development of Technologies for Controlling Debris Criticality

Accounting method for nuclear materials in fuel debris

◎ Objective

Japan is responsible for demonstrating that all the nuclear materials and activities in Japan remain used for peaceful purposes, through the International Atomic Energy Agency (IAEA), based on Japan-IAEA Safeguards Agreements. Though material accountancy is the primary technical measure for IAEA safeguards, it is difficult to apply the current accounting method, i.e. a fuel assembly is an accounting unit, to fuel debris produced in the accident because of its composition, shape, etc.

◎ R&D activities

The accounting methods and efforts carried out for the Three Mile Island accident and Chernobyl disaster are being investigated, comparing their situations with the Fukushima accident, and evaluating the applicability of those methods for Fukushima Daiichi NPP.

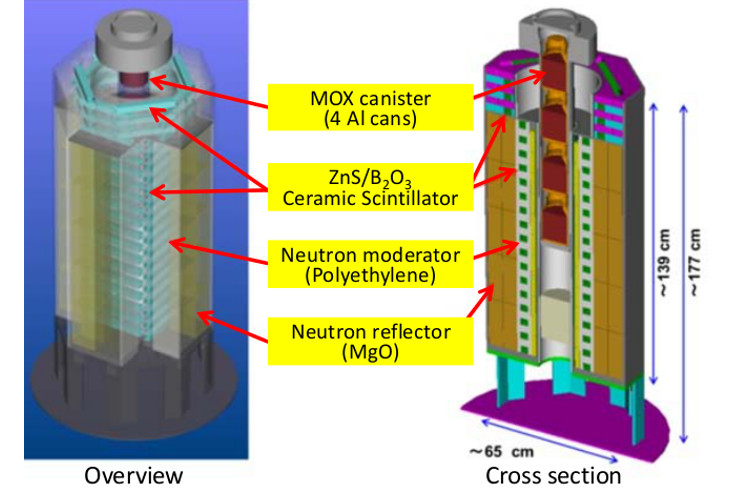

Based on the investigation, the measurement technologies applicable for fuel debris will be identified, and new measurement equipment will be developed. The technologies and equipment will be examined for their applicability and feasibility.

Measurement equipment with neutron detector using ceramic scintillator

This R&D contributes to part of the "Mid-and-Long-Term Roadmap towards the Decommissioning of TEPCO's Fukushima Daiichi Nuclear Power Station Units 1-4".

- (2-(3)-4) Formulation of Method for Quantification Management of Fuel Debris