Fuel Safety Research Group

Overview of Research Activity

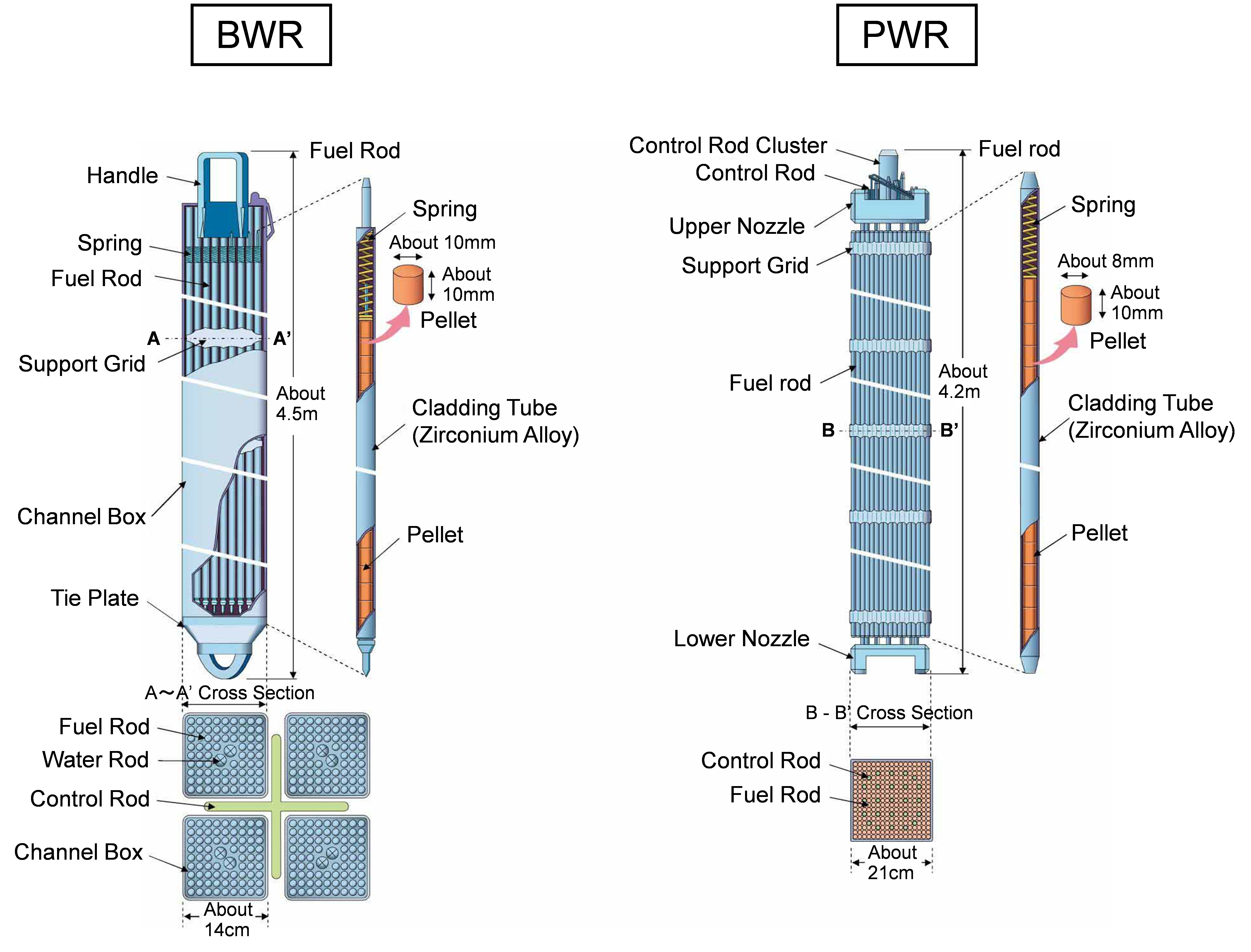

Fuel rods consisting of sintered pellets of uranium dioxide (or mixed oxide, MOX) and metallic cladding tube are commonly used in commercial light?water reactors (LWRs) (Fig. 1). Fuel Safety Research Group (FSRG) performs studies on the behaviors of fuels mainly under accident conditions to clarify fuel failure conditions and the influences of fuel failure on the safety of a nuclear power plant.

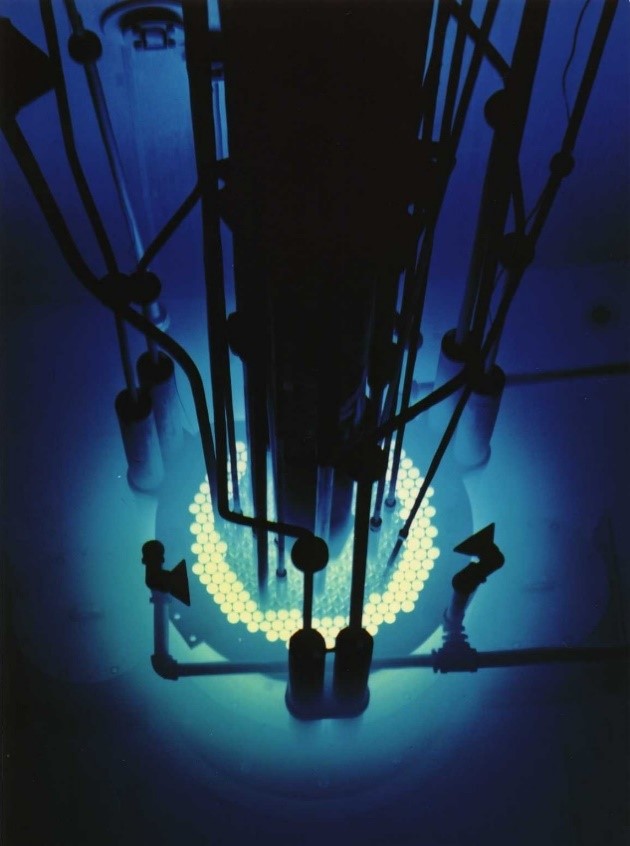

In designing a nuclear reactor, reactivity-initiated accidents (RIAs), in which rapid increase of reactor power occurs, must be considered as one of the design-basis accidents (DBAs) for safety evaluation. The nuclear safety research reactor (NSRR), which can introduce a rapid power increase (pulse operation), is used to simulate this RIA condition (Fig. 2). A test capsule containing a test fuel rod is loaded into the experimental cavity at the center of the reactor core, and then, a pulse operation is performed. In such an experiment, the behavior of fuel under RIA conditions can be investigated safely. Fuel behavior in a loss-of-coolant accident (LOCA), which is another main DBA in LWR design, is also investigated using a test apparatus that allows for the simulation of the cooling condition and the anticipated temperature history of the fuel rod during the postulated accident condition without using a nuclear reactor. The results of these experiments are analyzed by using fuel performance codes to verify and validate the models developed for predicting various phenomena observed under the accident conditions.

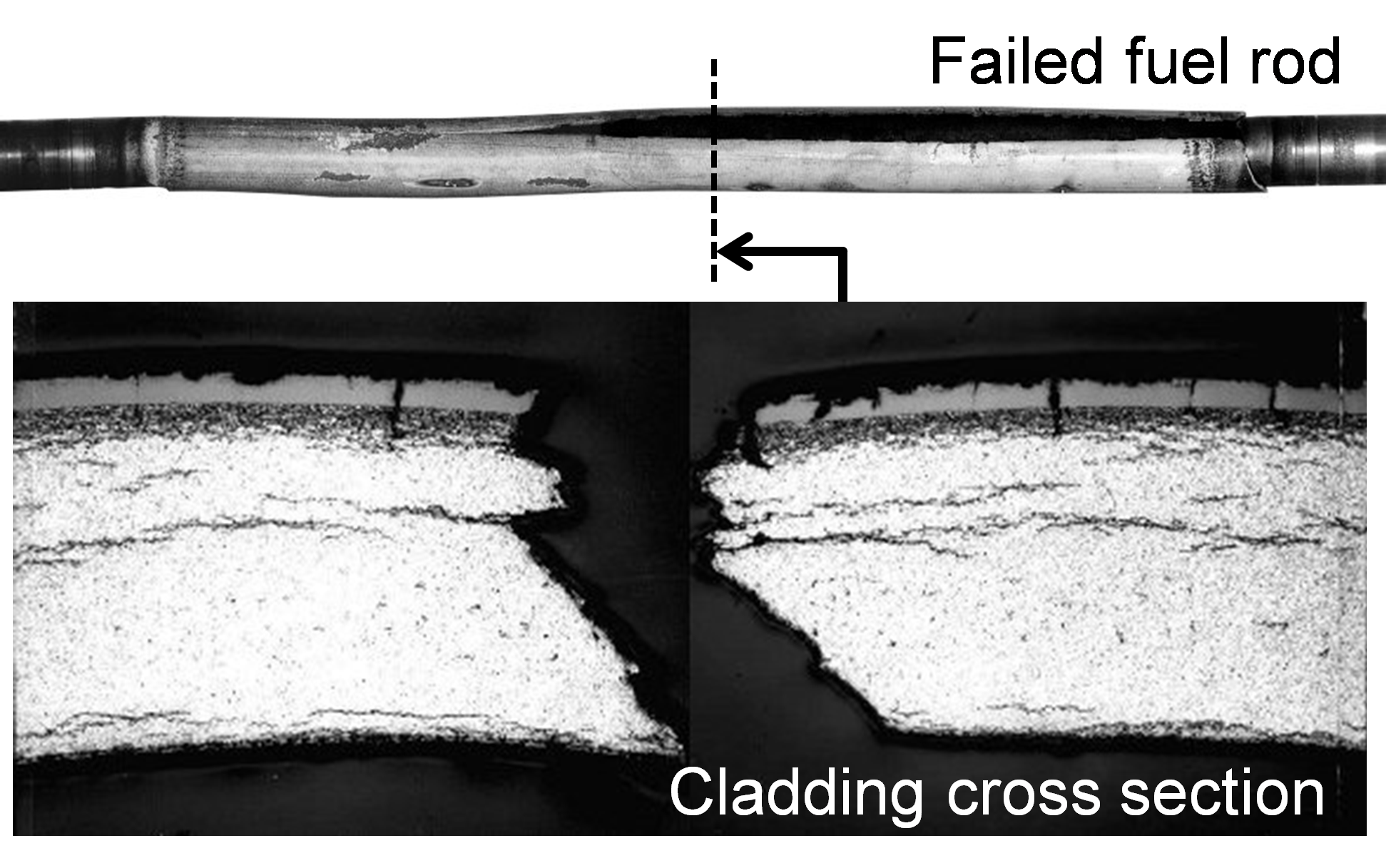

Currently, the research activity is to investigate the behavior of the fuels used in commercial LWRs over extended periods (high-burnup fuel). As burnup increases, various important changes occur in the state of the fuels, for example, surface corrosion of cladding tube and accumulation of fission products in fuel pellet. To ensure the safety of LWR plants that employ high-burnup fuels, it is necessary to investigate and understand the influence of such changes on the behaviors of fuels under not only normal operation conditions but also the accident conditions. Our research has revealed the details of various phenomena specific to high-burnup fuels that emerge under accident conditions and significantly influence fuel behavior, for example, fuel failure due to pellet-cladding mechanical interaction (PCMI) and rapid fission gas release (Fig. 3). We will continue our efforts to clarify the mechanisms of such phenomena for confirming fuel safety and improving the safety evaluation method. Moreover, we will expand the scope of our research to include new cladding materials and new types of nuclear fuels.

Another important research activity is to investigate the behaviors of fuels under conditions beyond DBA. In the Fukushima Daiichi accident in 2011, the fuels experienced more severe conditions than those postulated in the DBAs, resulting in the release of radioactive materials to the environment. We are extending our test conditions, test techniques, and capability of analytical tools to such severe accident conditions in order to support discussion and evaluation of the validity of accident management measures for preventing the escalation of an accident etc., which is now being planned to be introduced in commercial LWR plants.