January 08, 2015

Japan Atomic Energy Agency

Tanaka Precious Metals

Tanaka Holdings Co., Ltd.

[Key achievements]

Japan Atomic Energy Agency (Headquarters : Naka-gun, Ibaraki Prefecture, President: Shojiro Matsuura), and Tanaka Kikinzoku Kogyo K.K.1 (Head office: Chiyoda-ku, Tokyo; President & CEO Akira Tanae) have successfully developed a new hydrophobic3 platinum catalyst for collecting tritium2 at nuclear fusion reactors.

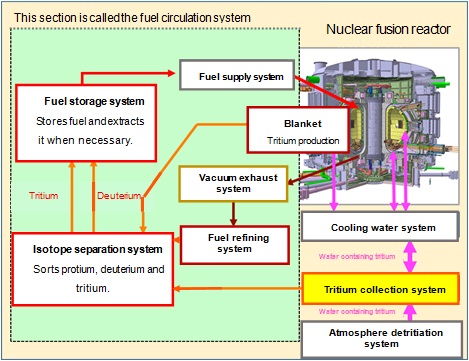

Nuclear fusion reactors use tritium as a fuel together with deuterium. Tritium is a rare substance and within nuclear fusion reactors, it uses a catalytic reaction to enrich as tritiated water and a system to collect it as tritium gas is required4.

Catalysts used to collect tritium are called “hydrophobic precious metal catalysts” based on precious metals such as platinum. In Japan, hydrophobic precious metal catalysts manufactured from polymers have been used for heavy water refinement6 at Advanced Thermal Reactor “Fugen Nuclear Power Station”5.

However, this catalyst has issues related to embrittlement to radiation and thermal stability. Therefore, these technological issues needed to be solved to allow for its application to nuclear fusion reactors requiring further enrichment from highly-concentrated tritiated water.

Therefore, the Japan Atomic Energy Agency and Tanaka Kikinzoku Kogyo K.K developed a new method of manufacturing catalysts involving hydrophobic processing with an inorganic substance base. As a result, previous technological issues were able to be solved with the development of a catalyst that exhibited no performance degradation in response to radiation application of 530kGy, a standard for radiation resistance, and maintenance of thermal stability at over 600°C, which is much higher than the 70°C temperature that is normally used. The catalyst created with this method was also confirmed to have achieved the world’s highest exchange efficiency, equivalent to 1.3 times the previously most powerful efficiency.

The application of this catalyst to the liquid phase catalytic exchange process7, is expected to overcome significant technological hurdles with regards to improving the reliability and efficiency of systems for collecting tritium from tritiated water.

It is also anticipated that the hydrophobic platinum catalyst manufacturing technology used for this catalyst could be applied to a wide range of fields other than nuclear fusion research. It was verified that if applied to a hydro oxidation catalyst8, hydrogen could be efficiently oxidized, even at room temperature. This catalyst can also contribute to improving safety at non-nuclear plants that use hydrogen in general by solving the aforementioned vulnerability issue.

The development of volume reducing and concentrating technology for tritiated water containing tens of billions to hundreds of billions of Becquerels per kilogram, which is produced in nuclear fusion reactors, is an important issue for research and development for nuclear fusion. Nuclear fusion plants use large amounts of radioactive tritium, a hydrogen isotope. Tritium is produced in the reactors of such plants using a reaction between lithium and neutrons. Some of this tritium mixes with coolant through high temperature metal and becomes tritiated water. An atmosphere detritiation system is also used to lower the amount of tritium emitted into the environment. This system uses an oxidation reactor to perform oxidation treatment on tritium within the atmosphere in the facilities for maintenance and repair of equipment within the reactor and collects and removes tritium after turning it into tritiated water.

To recycle the precious resource of tritium as fuel, a tritium collection system has been installed that enriches tritium water collected in the nuclear fusion plant and changes it back into gas.

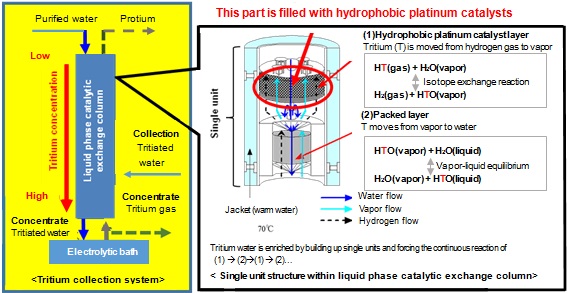

Specifically, collected tritiated water is contacted with a catalyst that makes hydrogen isotope exchange between protium gas (normal hydrogen gas) and tritiated moisture possible, before being reduced in volume and enriched. Because general catalysts lose catalyst performance in a moist atmosphere, catalysts must be highly hydrophobic so that they can be activated even in a highly moist atmosphere. The development of a hydrophobic catalyst had been a significant technological hurdle that had made creating a system to collect tritium from tritiated water technologically difficult.

We have previously used hydrophobic polymers to manufacture a number of hydrophobic precious metal catalysts that can be used to enrich and reduce the volume of tritiated water. In Japan, such catalysts have been used for heavy water refinement at the Advanced Thermal Reactor “Fugen Nuclear Power Station”. However, catalysts manufactured from polymers have presented problems related to radiation effects and heat-resistant technology required for application to nuclear fusion. Another problem was the high manufacturing cost. This research has used a new concept of applying catalyzing technology after making inorganic substances hydrophobic. In the catalyst manufacturing process, various parameters other than methods for making inorganic substances hydrophobic exist. These include support9 for the platinum forming the catalyst, the surface state of the inorganic substance, and pore diameter10. We evaluated how these parameters affected catalyst performance with an experiment of the exchange efficiency for hydrogen isotopes between tritium and vapor. We optimized the manufacturing parameters based on the results and were able to successfully develop a high-performance catalyst.

Compared to the previous catalyst manufactured from polymers susceptible to radiation in general, which was used for heavy water refinement at the Advanced Thermal Reactor “Fugen Nuclear Power Station”, the performance of this newly developed catalyst is not affected even by a radiation dose of 530 kGy. Such a dose is equivalent to continuous processing of water containing 9 trillion Becquerels per kilogram for two years. Furthermore, compared to previous catalysts using polymers that generally offered low thermal stability and could even burn out under some conditions, this catalyst has confirmed thermal stability for temperatures of over 600°C, which is much higher than the normal usage temperature of 70°C. Therefore, this newly developed catalyst solves the various problems related to application to systems responsible for tritium safety. Moreover, tritium-vapor hydrogen isotope exchange efficiency is approximately 1.3 times (world’s highest) that of the previously most powerful product per catalyst volume. This signifies that the same performance can be achieved with a catalyst weight three quarters that of previous catalysts. The application of this catalyst to the liquid phase catalytic exchange process can increase the concentration of tritium in tritiated water, making it possible to efficiently collect tritium from tritiated water. It can also reduce the amount of catalyst used, lowers manufacturing costs as it is made from an inorganic substance, and also contributes to the cost-efficient collection of tritium from tritiated water requiring a large amount of catalysts. The development of this catalyst is expected to overcome a significant technological hurdle for the verification of a system for collecting tritium from tritiated water. A joint patent application has been made for this catalyst technology by the Japan Atomic Energy Agency and Tanaka Kikinzoku Kogyo K.K.

This catalyst was manufactured by means of a new method. Therefore, a current issue before practical implementation is steadily proceeding with validation experiments to test elements such as long-term performance stability by confirming that no decrease in performance is observed after long-term repeated use. It is also anticipated that the manufacturing technology used to create this hydrophobic platinum catalyst could be widely applied to other fields. For example, if applied to the manufacture of oxidation catalysts, this technology has already been proven to efficiently oxidize hydrogen in a wide range of concentrations even at room temperature, whereas conventional catalysts could not perform hydrogen oxidation without being heated. As we are now entering a “hydrogen society” that uses large amounts of hydrogen as an energy source, this function could also be promising for recombiners for preventing hydrogen detonation during accidents and power outages. Therefore, as this catalyst has solved the aforementioned vulnerability issue, it could not only greatly increase the overall stability of nuclear fusion reactors, but also contribute to improving the stability of non-nuclear, general hydrogen plants.

Core company developing manufacturing businesses in the TANAKA KIKINZOKU GROUP, with TANAKA HOLDINGS Co., Ltd. as its holding company.

http://pro.tanaka.co.jp/en/topics/

http://pro.tanaka.co.jp/en/topics/fileout.html?f=166

Radioactive isotope of hydrogen. Also known as hydrogen-3.

A property describing having low affinity to water and being resistant dissolving in water.

A fuel recycling system refers to treating and extracting impurities generated in the reactor core of nuclear fusion reactors that are emitted with unburnt fuel before recycling them as fuel components and re-supplying them to the reactor core plasma. Fuel recycling systems can be broadly divided into five types. These are 1) vacuum exhaust system for discharging plasma exhaust from the nuclear core, 2) fuel refinement system for separating and collecting hydrogen isotope components from plasma exhaust, 3) isotope separation system for separating and collecting fuel components by separating hydrogen according to isotope, 4) fuel storage system for storing fuel components and 5) fuel supply system for supply fuel to reactor core plasma. The amount of tritium consumed as fuel during nuclear fusion can also be complemented by production in the blanket within the reactor. Because long-term operation may cause tritium to become mixed into the coolant via metal, a system for collecting tritium from large amounts of tritiated water is required. Accordingly, the development of a catalyst that could reduce the size and improve the efficiency of such a system for collecting tritium from tritiated water and also be used for highly-concentrated tritium had been an unresolved issue.

As a thermal reactor, it established Japan's plutonium recycling technology through the world's largest utilization of MOX (Mixed Oxide) fuel assemblies. It is now being decommissioned.

This refers to re-enriching degraded heavy water with a lowered concentration due to contamination by light water to nuclear reactor-grade heavy water at a concentration that allows it to be used as a nuclear reactor moderator.

Systems for collecting tritium from tritiated water are composed of a liquid phase catalytic exchange column that enriches tritiated water by moving tritium into water via vapor from hydrogen, and an electrolytic cell that converts the enriched tritiated water into enriched tritium gas by means of electrolysis. Units comprising sets of reaction and absorption sites (packed layer) are accumulated in the liquid phase catalytic exchange column. Tritium moves from hydrogen to vapor in the reaction site and from vapor to water in the absorption site. By forcing this reaction to occur continuously, tritiated water is gradually enriched toward the bottom of the column. The catalyst developed here is used in the catalyst part of this process. A highly-stable catalyst is required to perform the catalytic process over long periods of time. The catalyst developed here maintains non-combustibility required of facilities that use tritium, has improved radiation resistance, which had been a problem during high concentration of tritiated water, and is highly reactive. Therefore, it can increase tritiated water concentration regardless of tritium concentration.

These catalysts, with added hydrophobic capability, can perform efficient oxidation of hydrogen even at or close to room temperature without suppressing reaction to vapor. Even room temperature oxidation of extremely low concentration hydrogen is possible.

Catalysts contain many fine platinum particles scattered on the surface of an inorganic substance. The amount of platinum that can be placed on the surface is referred to as support. It is shown as platinum weight per inorganic substance volume.

Inorganic substances used as catalysts contain many small pores. Pore diameter refers to the mean diameter of these pores. The presence of this large number of pores means that can increase platinum support per volume on catalyst surface area.

[ BACK ]