| @@ | ||

|

|

||

|

@Tests at Actual-scale Facilities |

||

The full-scale facilities (deuterium criticality assemblies, safety test facility, heat transfer loop, component test loop) were built at O-arai Engineering Center. In those facilities, many experiments and examinations (confirmation of nuclear properties in the core, heat transfer characteristics, coolant characteristics in an accident) were implemented to obtain the data required for the designing. Based on the assessment and verification of those data, original design methods and analysis code were developed. For the components unique for the ATR core, we took a step-by-step procedure, repeating trial fabrications, tests, and improvements to prove their performance, reliability, and durability. The self-dependent development principle was demonstrated in such research and development activities. |

Deuterium Criticality Assembly (DCA) |

ĦDeuterium Criticality Tests Various examinations were performed including criticality test using enriched uranium and MOX fuel to obtain the data for core design and safety assessment of Fugen. Other valuable data were also provided for the accuracy assessment of operational controllability and core characteristics analysis code. |

|||||

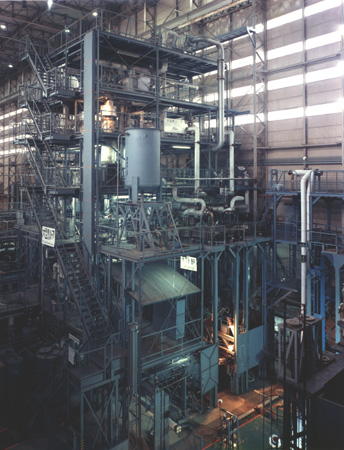

14MW Heat Transfer Loop (HTL) |

||||||

ĦHeat Transfer Tests HTL having capacity up to 14MW in heating provided means to study heat removal behavior in water-cooled fuel. Obtained data not only verified ATR fuel's high performance and robustness under severe condition but also applied to thermal hydraulics design of fuel assembly and development of a thermal hydraulics analysis code. |

||||||