Low-cost and Labor-Saving Method for Replacement of Acrylic Panels of a Large Glove Box

Innovative Panel Replacement Technique Using Bag-in/Bag-Out Method

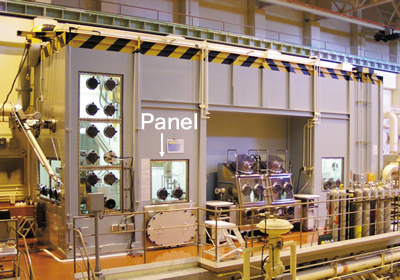

A large glove box (LGB) (Fig.12-3) has been extensively used for the examination of transuranium elements at the WAste Safety TEsting Facility (WASTEF). The acrylic panels of this LGB were found to be damaged and were to be replaced.

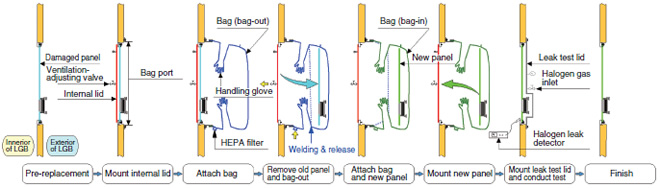

In the conventional procedure for panel replacement, the panels to be replaced are opened inside a large greenhouse adjoining the LGB to prevent the dispersion of contamination. The operations are performed by workers wearing airline suits. However, this procedure has some drawbacks: the greenhouse should have a large space and the inside of the LGB needs decontamination. To improve the safety and efficiency of the replacement operation, a replacement method based on the bag-in/bag-out method was developed. Normally, the bag-in/bag-out method is not suitable for the handling of large items like LGB panels. The negative inner pressure of the LGB generated a suction force proportionate to the size of the transfer bag. An internal lid was introduced at the opening of the LGB to isolate the area of negative pressure (Fig.12-4). The internal lid prevents the suction of the bag and made it possible to apply the bag-in/bag-out method to replace the LGB s panel.

The internal lid is equipped with a ventilation-adjusting valve to release and control the air pressure in the bag. The use of this valve improved the safety and efficiency of the replacement process. The bags are equipped with a highefficiency particulate air (HEPA) filter to control the air flow from the outside to the inside of the LGB so as to prevent contamination dispersion and reduce the operation time. Another lid, called“ leak test lid,” equipped with a halogen gas inlet was developed to easily carry out the leak test (halogen gas leak test method) during/after the replacement.

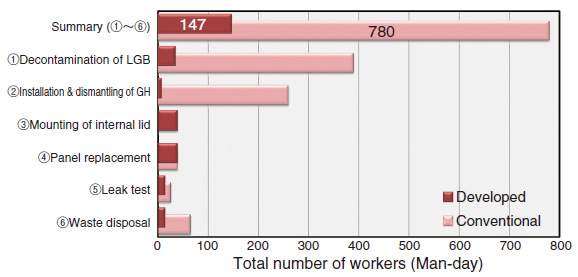

The results of the performance test for the developed method by using an actual LGB were as follows: (1) Safe and effective replacement of the panel was carried out in the narrow area and (2) the number of days required for the replacement operation was reduced to approximately onethird and the total number of workers required was reduced to approximately one-fifth compared to the requirements of the conventional method (Fig.12-5). In addition, the volume of waste generated in the new method was reduced to approximately one-third of that generated in the conventional method.

The performance test showed that the developed replacement technique was safe, cost-efficient, and laborsaving; therefore, it is expected to be used widely in the field of maintenance of nuclear facilities.

Reference

kuraba, N. et al., Replacement Technology for Front Acrylic Panels of a Large-Sized Glove Box Using Bag-in/Bag-out Method, JAEA-Technology 2009-071, 2010, 34p. (in Japanese).

Fig.12-3 Appearance of a large glove box(LGB)

The damaged panel behind the LGB needed replacement at the narrow space.

Fig.12-5 Comparison between conventional developed methods

The total number of workers required for the developed method is approx. one-fifth of that required for the conventional method.

Fig.12-4 Panel replacement procedure with the developed method

An Internal lid facilitated the application of the“ bag-in/bag-out” method to the panel replacement of the panel of the LGB.