Supplementary document

1. Background

JAERI (Japan Atomic Energy Research Institute), one of the former

institutes of JAEA, has selected novel technologies with higher

potentials for industrial use, and exhibited them through such

as technology fairs, in order to actively transfer the R&D

results to industrial entities.

In this development, we have actively engaged in the whole process of:

- Selection of promising technologies for practical applications.

- Introducing them at technology-transfer fairs and at catalogues.

- Detailed technical consultation for visited companies.

- Contract and execution of patent enforcement consents and technical

guidances.

- Set up a special team for executing a definite support to manufacturers

that will commercialize.

- Further joint development meet for demand of product specifications

from customers.

- Keep confidential if necessary.

In terms of the effective use of intellectual property rights,

there were formerly a few examples of the practical use of patent

enforcement consents to companies. However, due to insufficient

participation of the research organization side for the necessary

follow-up development, an essential effort for the utilization/commercialization

was implemented mainly by the company side, so that contribution

by the organization side was reduced or underestimated. Based on

these reconsideration, we actively and systematically work as a

development project of the industry-organization co-operation, particularly

for the technology in which the utilization/commercialization is

highly anticipated.

2. Social contribution by commercialization

The main characteristic of this technology is that we can measure

a weight of the impurity gas released from measuring objects such

as aluminum casting parts, with a small sample, a short time and

a high accuracy, by using a small movable device.

This technology opens the new application of quality control not

only for the meltdown aluminum, also for other many materials.

It is also expected to deeply contribute for securing security

and safety of cast products widely used in our life.

3. Technical contents

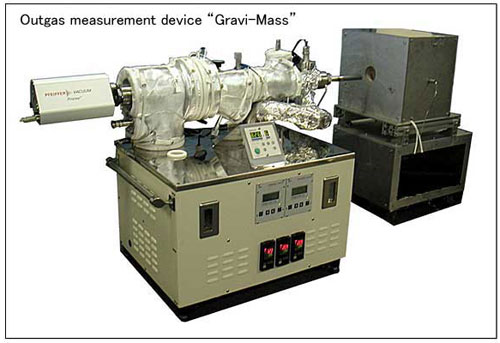

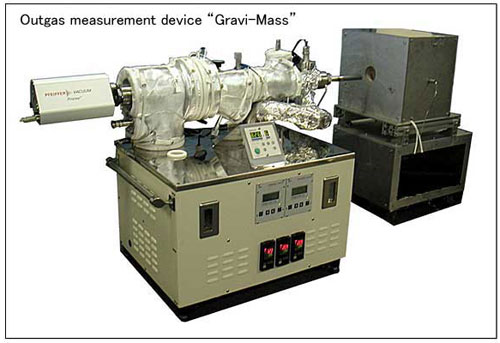

The new “Gravi-Mass” we have developed, consists of

an electric furnace that heats a sample metal such as aluminum,

a vacuum chamber and a gas analysis sensor (Quadrupole Mass Spectrometer:

QMS). This system can analyze many sort of gases released from

a metal sample at the same time. A direct analysis of the sample

gas to be measured is also possible by introducing the gas to

an inlet port.

In a conventional gas analysis method, the gas quantity was expressed

by density which is the volume value (cm3/g), however, a precise

monitoring of a circumference such as temperature and pressure

was indispensable to calculate the gas quantity, because the volume

value was, in principle, influenced severely by the temperature

and the pressure (a gas volumetry method). Therefore, this method

has an intrinsic disadvantage of deteriorating the accuracy, when

the sample gas temperature and pressure fluctuate during analysis.

In addition, when we compare the results of measurement values

among analyzing organizations, the measurement conditions should

be converted by the same standard.

The new Gravi-Mass method we have developed, measures the gas

quantity by its weight. This absolute measurement is no need to

consider the fluctuation of the gas temperature and pressure.

Therefore, it has been possible to secure the traceability (history

management) which can reproduce the measured value without being

influenced by the measurement conditions (refer to the table below).

| Influencing factor |

Gas volmetry method |

Gravi-Mass method |

| Circumference (temperature, pressure) |

The fluctuations of values should be monitored during a measurement time, in every measurement day and measurement place, and the values measured should be converted by the same standard. |

No need to consider. |

| Sample temperature |

A temperature of the sample gas varies with temperature fluctuations of the device, which causes an error of temperature. |

Not influenced. |

| Sample pressure |

In case a number of unknown gases are included, it causes a pressure error because it is actually impossible to identify the partial pressures of all gases. |

Not influenced. |

| |

At present, it applies only to hydrogen. |

|

Back to the article

Back to the article