| ACHIEVEMENTS IN DEVELOPMENT OF | |||||

|

|

|||||

|

Development of Water Chemistry Management Technology |

|||||

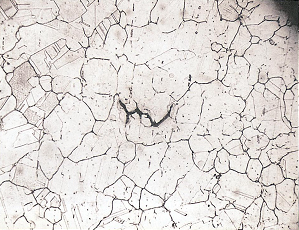

At nuclear power plants using light water as a reactor coolant, the water chemistry control is extremely important in order to prevent stress corrosion cracking (SCC) of stainless steel and to reduce radiation exposure during maintenance work, in terms of ensuring the safety and reliability of the plants. Even nuclear power plants of the same type differ in the materials used and in operating history plant by plant. The most appropriate water chemistry management should be independently established for each plant. Following troubles of SCC found in 1980 at Fugen, efforts were focused on the technological improvement of water chemistry control for the coolant, which has led to one of the greatest achievements in the world, contributing to the measures for LWRs. (1) Hydrogen Injection Technology

At Fugen, hydrogen is injected into the coolant in order to prevent SCC in terms of reducing dissolved oxygen that causes SCC. It helps improve the environment of water chemistry. The application of hydrogen injection at Fugen was the first trial in Japan. Detailed surveys, thorough material testing, and short-term injection tests had been conducted to fully investigate the effectiveness of hydrogen injection and the impact on the plant before continuous injection was started in December 1985. The corrosion potential of |

|||||

|

|||||

stainless steel was measured with in-plant test device, and the changes of 60Co concentration in the coolant were traced and evaluated at the time of hydrogen injection. The obtained data have been highly appraised by experts in Japan and other countries. |

|