Structural Integrity Research Group

Research on Material Aging Degradation and Structural Reliability of Reactor Components and Structures Related to Reactor Safety

We research evaluation methods on the structural integrity of safety-critical components and structures in light-water-type nuclear power plants.

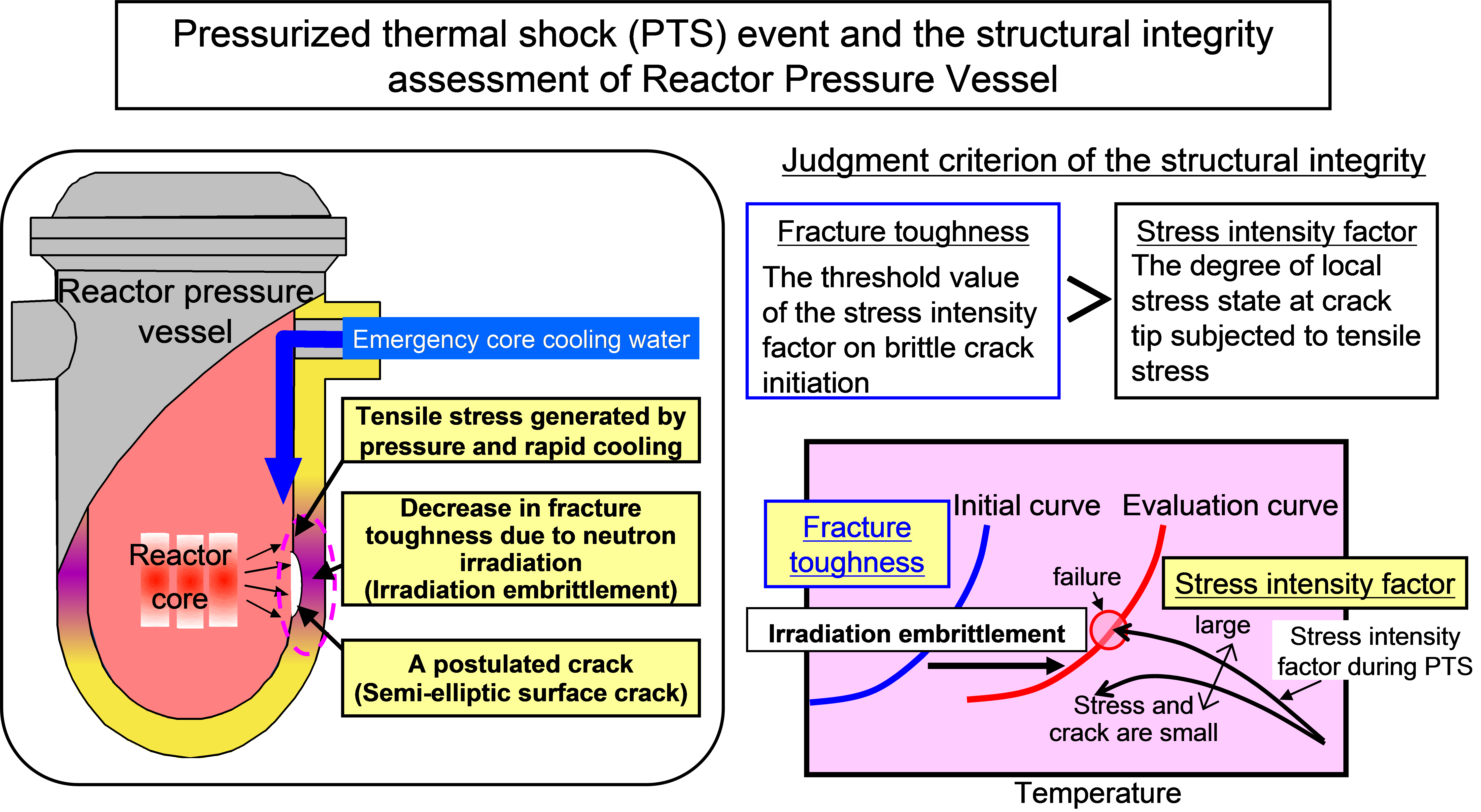

In researching material degradation, we focus on radiation damage to structural materials which are specific to the construction of nuclear reactors; neutron-irradiation embrittlement of the steel comprising a reactor pressure vessel steel is the primary target of our research in this area.

Concerning the structural integrity evaluation, an enhanced evaluation approach is under development based on fracture mechanics considering material degradation, the frequency and accuracy of inspection, weld residual stresses, and the existence of cracks from operation or caused during manufacturing.

Components of concern are the reactor pressure vessel and major piping of the reactor coolant pressure boundary, both of which are especially important for securing reactor safety.

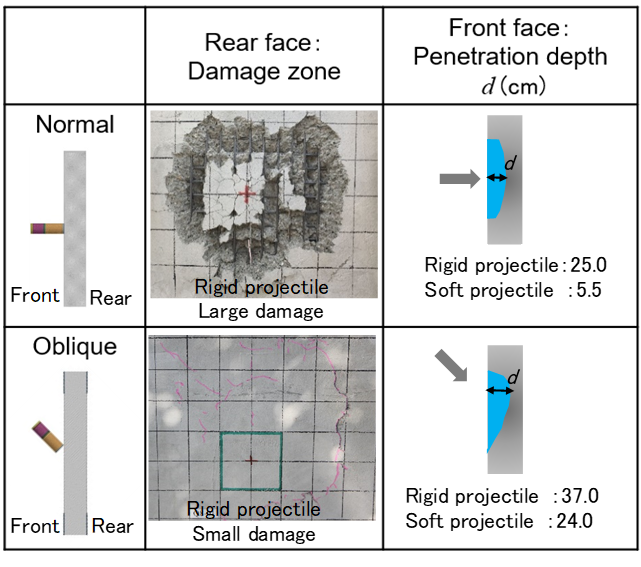

In researching external events, we focus on structural integrity assessment to reactor building, equipment and piping subjected to earthquake and projectile impact.

The following research activities have been conducted.

- (1) Neutron-irradiation embrittlement of reactor pressure vessel (RPV) steels:

We are studying the mechanism of irradiation damage of RPV steels by ultrafine analyses of nanometer-scale structures in specimens irradiated by a test reactor or accelerator for improving the evaluation method for the decrease of fracture resistance caused by irradiation.

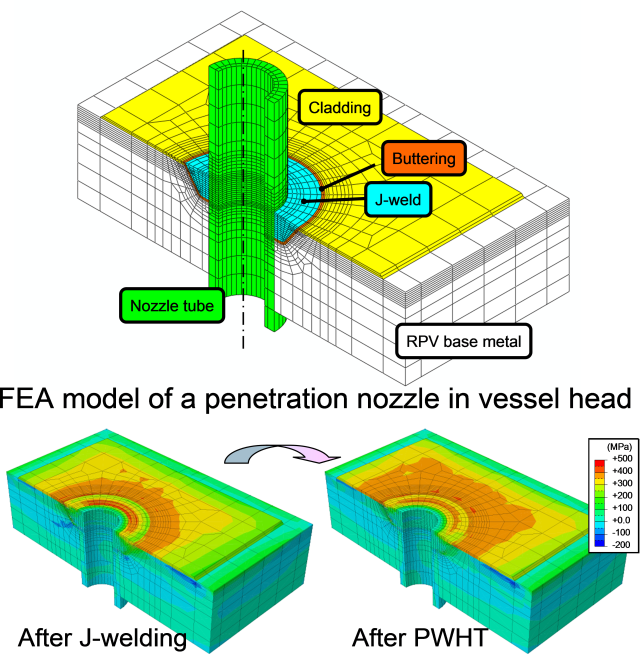

- (2) Structural integrity assessment for structural and/or material discontinuous joints:

We are studying special structures, such as geometrically complex welds or dissimilar metal welds, based on the residual stress evaluation by finite element analysis (FEA) and fracture mechanics to establish methodologies for assessing the structural integrity of welded joints.

- (3) Probabilistic fracture mechanics analysis method:

We are developing computational analysis codes for calculating a failure probability of RPV with irradiation embrittlement under the pressurized thermal shock event and a damage probability for piping with progressive stress corrosion cracking or wall thinning, considering the varieties and uncertainties of material properties, residual stress near welded zone, operational and seismic loads and accuracy of flaw inspections.

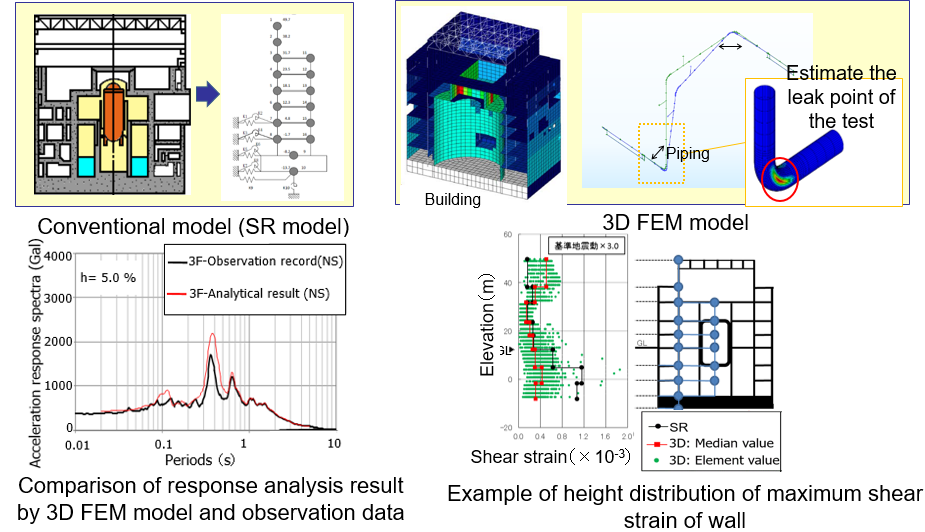

- (4) Seismic safety evaluation methodology:

We are conducting an experimental study on the crack-growth behavior of reactor coolant system piping under excessive load caused by a large-scale earthquake and the development of a structural integrity assessment method based on probabilistic fracture mechanics.

- (5) Structural integrity assessment to reactor building, equipment and piping subjected to earthquake:

We are developing and standardizing seismic response analysis methods for building using 3D FEM model, we are also improving a fragility evaluation method that contributes to seismic probabilistic risk assessment (SPRA) for safety-related important structures and components such as reactor building, equipment and piping. Moreover, R&D on validation of 3D response analysis method using seismic observation records, etc. measured in the HTTR, JAEA has just started1)

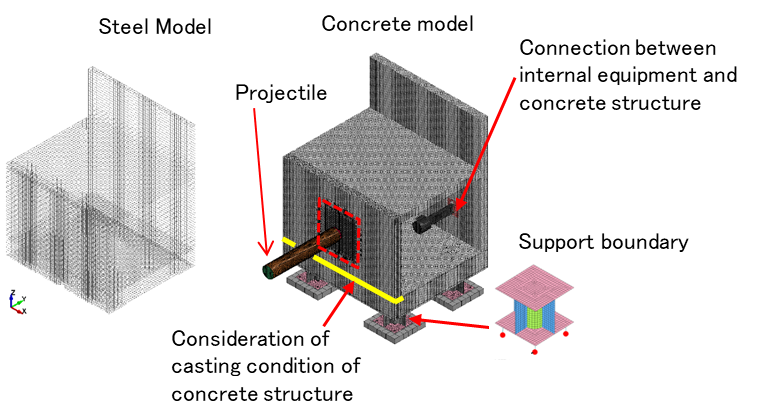

1) https://www.jaea.go.jp/02/press2019/p20032401/ - (6) Structural integrity assessment to reactor building, equipment and piping subjected to projectile impact:

We are developing the evaluation method for local damage to reinforced concrete structure subjected to normal and oblique impact. We are also focusing on the investigation on the transmission of induced vibrations by projectile impact among the connected floors and walls of the reinforced concrete structure with internal equipment.

Figure 1 Integrity assessment of RPV with neutron irradiation embrittlement under pressurized thermal shock.

Figure 2 Comparison of residual stress distributions near J-welds of penetration before and after post-weld heat treatment (PWHT). Residual stress near J-welds decreases by PWHT, whereas tensile stress within cladding increases to almost yield stress.

Figure 3 Example of structural integrity assessment to reactor building, equipment and piping subjected to earthquake.

Figure 4 Example of impact tests for RC panel.

Figure 5 Example of evaluation for the effect of stress wave propagation on internal equipment.